EAW. Added Value: Innovation.

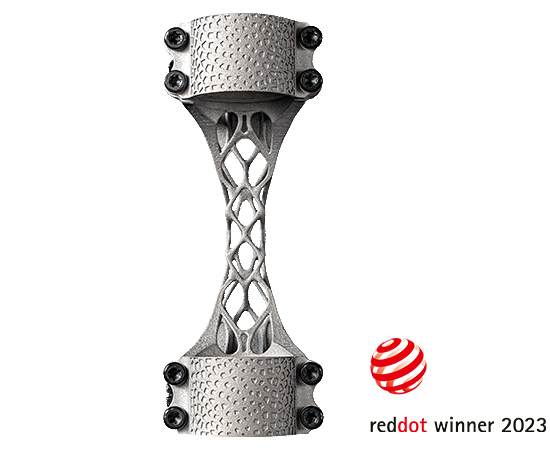

EAW launches the new 3D Ultralight Mount made of titanium. The revolutionary bionic design has received the Red Dot Award: Product Design 2023.

The future of scope mounts

The mount comes in a new revolutionary bionic design for mounts which is inspired by nature. Allowing for a very light overall weight while being extremely durable, this design represents the future of mounts to come.

EAW´s usual test was carried out with great success by the DEVA institute. The mount prooved to be extremely durable – after 2000 shocks with 700G of force, the mount did not show any signs of wearing off!

The new EAW Ultralight Titanium Mount

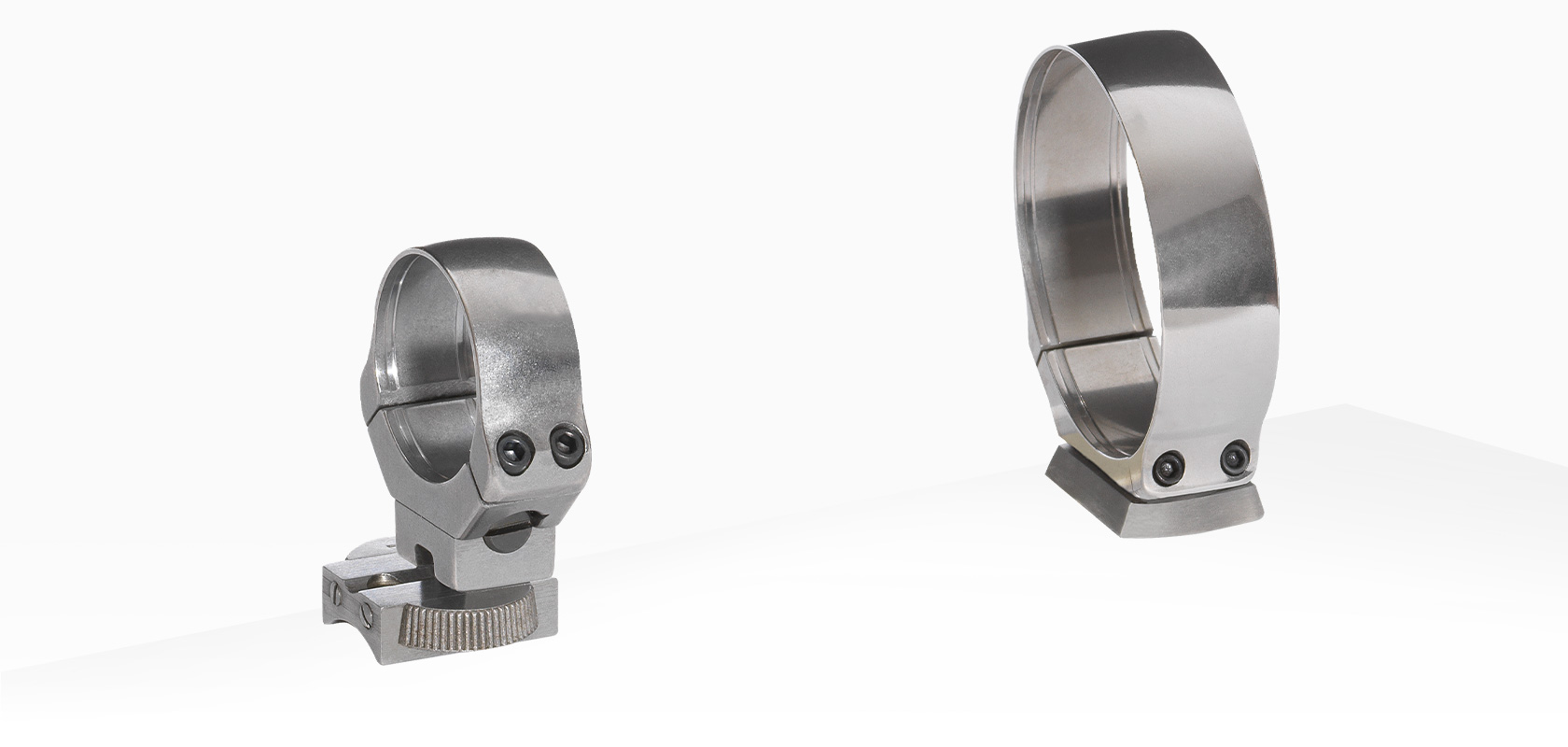

Customers have the option of ordering the mount with either a multiscrew or a repeatable lever.

- Revolutionary bionic design

- The new design has received the Red Dot Award: Product Design 2023.

- Available in Ø30mm or Ø34mm diameter.

- It is now available against pre order.

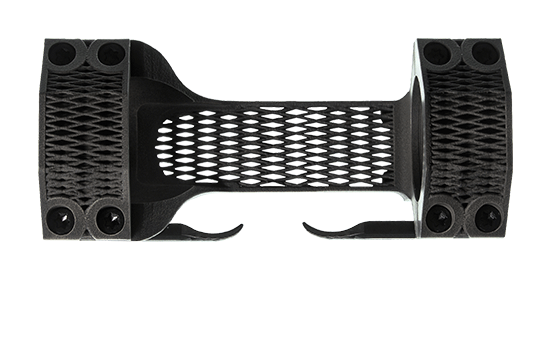

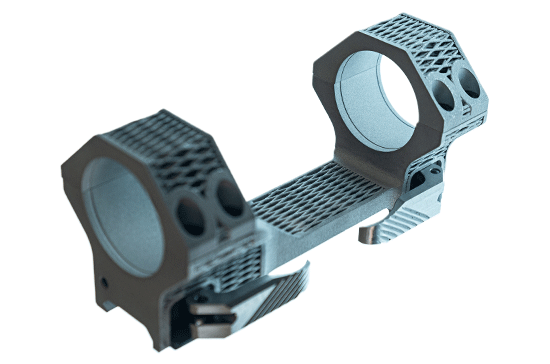

EAW Ultralight Aluminium Mount

- Manufactured using the worldwide unique laser-based additive manufacturing process

- Extremely lightweight aluminium block mount which saves 30-40 % in weight against comparable mounts

- Post-processing by our high-quality milling and turning machine

- Novel design through innovative lattice construction

- DEVA tested with 2000 shocks at 700g

- Available in diameters of 30 and 34 mm, in two heights each

- Available in natural or black anodised aluminium

- Coating possible

- Only made to advance order

Innovation out of Tradition

The traditional manufacturer EAW, which redefined the market for mounts in the 1970s with the invention of the pivot mount, proudly presents another world first: The new aluminium mount, produced by a laser in an innovative additive manufacturing process. It is not only impressive because of its special appearance and enormous rigidity, but above all because of the revolutionary weight saving of approx. 30-40% compared with conventional mounts.

According to Stefan Schilling, Managing Director of EAW, this new form of mount production has already been registered as a patent and confirmed by a certificate. Furthermore, in order to meet EAW’s own high quality standards, the mount has already been successfully subjected to endurance testing by DEVA with 2000 shocks at 700g.

“We spent a long time developing this technology, so we are particularly proud that the EAW team can once again present a world first that will revolutionise the market for mounts.”

Stefan Schilling (Managing Director of EAW)

Press area

Downloads

Official Press Release

Optimised for Print (CMYK – 300dpi)

Optimised for Web (RGB – 72ppi)